Quality

Quality Management System

Six Sigma Microelectronics is committed to providing high-quality products and services to meet customer requirements and exceed expectations. This is achieved through the company’s mature Quality Management System (QMS) that is certified to AS9100, ISO 9001, MIL-STD-883, and MIL-PRF-38535.

The company’s robust QMS ensures that systematic processes, rigorous evaluations, and proactive risk management are incorporated into all of its business activities.

Six Sigma’s highly skilled and experienced team continually monitors and enhances processes, ensuring that the components processed are of the highest quality and reliability.

Six Sigma always prioritizes the reliability of the microelectronic components first in its decision-making process. Customers can count on Six Sigma to always do the right thing!

Quality Assurance and Quality Control

Six Sigma’s Quality Assurance (QA) department is organized as an independent group that is responsible for assuring product quality, QMS compliance, and acting as the voice-of-the-customer. Quality Assurance personnel have the exclusive authority to release a product for shipment based upon defined criteria including: product quality, workmanship, and satisfactory completion of requirements.

Six Sigma has multiple quality assurance and quality control inspection points to ensure that customer, government, and industry standards are met. This starts with Contract Review and goes all the way through the final authorization to ship (Final QA). The company also flows down customer quality clauses, including FAR and DFAR requirements, to its suppliers through purchasing contracts and specifications.

All monitoring and measuring equipment used to verify product conformity are calibrated in accordance with ANSI/NCSL Z540-1, ANSI/NCSL Z540.3, and/or ISO/IEC 17025. All measurements are traceable to the National Institute of Standards and Technology (NIST) or a natural or physical constant

Counterfeit Mitigation Program

Six Sigma has a Counterfeit Mitigation Program in accordance with SAE AS5553 for the prevention of counterfeit (or suspect fraudulent) part use and their inclusion in product delivered to customer. The Counterfeit Mitigation program includes:

- Training of all personnel in the awareness and prevention of counterfeit parts;

- Controls over external supplier/customer products;

- Requirements for assuring traceability of parts and components;

- Verification and test methodologies to detect counterfeit parts;

- Quarantine and reporting of suspect or detected counterfeit parts.

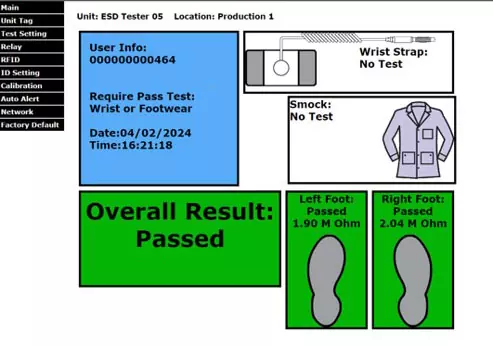

ESD Program

Six Sigma’s Electrostatic Discharge (ESD) Control Program is in accordance with ANSI/ESD S20.20 and JESD625. This program ensures electronic components and items that are susceptible to ESD damage are protected. The ESD Control Program includes:

- Training of all personnel, contractors, and visitors in the awareness and prevention of ESD damage;

- Controlled facilities (conductive flooring, humidity controls, constant wrist strap monitors, air ionizers, work surfaces, seating, shelving, mobile equipment);

- Personnel grounding (wrist straps, footwear, smocks);

- Routine testing and verification of grounding/equipotential bonding systems.

Others

Defense Priorities and Allocations System (DPAS)

Six Sigma routinely processes DX and DO rated orders in accordance with 15 CFR 700.

Conflict Mineral Policy Statement

Six Sigma Microelectronics is committed to sourcing materials from companies that share its values regarding respect for human rights, integrity, and environmental responsibility.

The company is committed to complying with the OECD* Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas, as well as Section 1502 of the Dodd-Frank Act, which aims to prevent the use of minerals that directly or indirectly finance or benefit armed groups in the Democratic Republic of the Congo (DRC) or in adjoining countries (“conflict minerals”).

Suppliers that provide materials containing tin, tantalum, tungsten, or gold to Six Sigma are required to commit to sourcing only from smelters that have obtained a “conflict-free” designation from an independent, third-party auditor. Each in-scope supplier is required to provide completed Responsible Minerals Initiative Conflict Minerals Reporting Template declarations evidencing such supplier’s commitment to the foregoing and documenting countries of origin for the tin, tantalum, tungsten, and gold that it purchases.

* Organization for Economic Co-operation and Development

Military and Industry Standards Compliance

Six Sigma Microelectronics also operates in compliance with the following standards:

- ANSI/ESD S20.20: Protection of Electrical and Electronic Parts Assemblies, and Equipment

- JESD625: Requirements for Handling ESD Sensitive Devices

- SAE AS9003: Inspection and Test Quality System

- ANSI/NCSL Z540: Calibration Laboratories and Measuring and Test Equipment

- ISO 10012: Requirements for Measurement Processes and Measuring Equipment

- MIL-PRF-38535: Integrated Circuits (Microcircuits) Manufacturing

- MIL-PRF-38534: General Specification for Hybrid Microcircuits

- MIL-PRF-19500: General Specification for Semiconductor Devices

- J-STD-002: Solderability Tests for Component Leads

- MIL-STD-883: Test Method Standard, Microcircuits

- MIL-STD-750: Test Method Standard for Semiconductor Devices

- MIL-STD-202: Test Method Standard, Electronic Component Parts

- SAE AS5553: Counterfeit Electrical, Electronic, and Electromechanical (EEE) Parts; Avoidance, Detection, Mitigation, and Disposition

Registrations

- ITAR Registered (Letter)

- System for Award Management (SAM.gov)

- Online Aerospace Supplier Information System (OASIS Database)

Certifications

- AS9100 and ISO 9001 Certified | Certificate (PDF)

- QML Status: Full QML-Q, V & Y Certification/Qualification | MIL-PRF-38535 QML List

- DLA Lab Suitability | Certificate (PDF) | Letter (PDF)

- DLA QML Class Q, V, and Y certified for column attach and hot solder dip, a subset of assembly services | Certificate (PDF) | Letter (PDF)