Test Services

Solderability Test

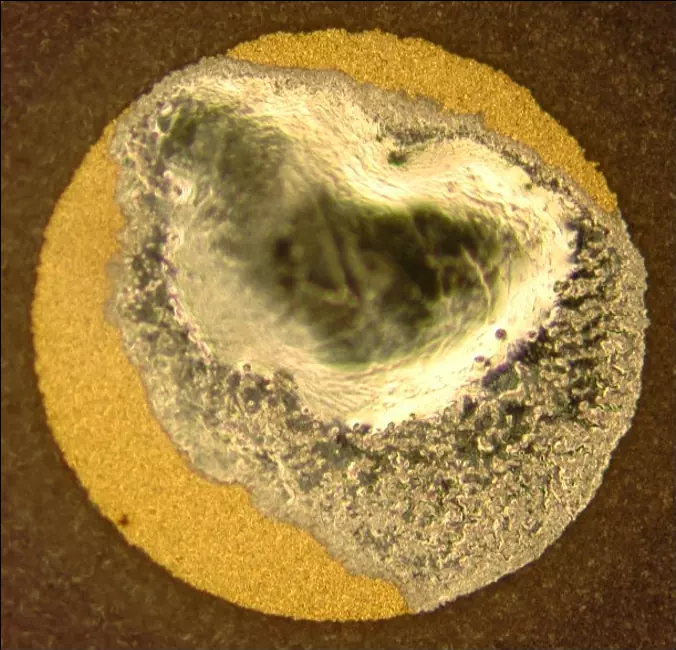

Solderability test is used to determine the solderability of leads and terminations which are normally joined by a soldering operation. This determination is based on the ability of the terminations to be wetted by the molten solder. The test provides for accelerated aging (steam conditioning) in order to simulate the condition of the components after long-term storage.

Dip and look solderability test is performed by first subjecting the components to pre-conditioning (steamaging or dry bake). After pre-conditioning, the components’ terminations are dipped into the solder in a controlled fashion using a specific rosin-activated fluxes. After dipping, the components are inspected to the criteria specified.

Surface mount simulation test is performed by screen-printing a specific solder paste onto a ceramic plate or FR-4 substrate (for CGAs) then placing the component onto the paste, followed by a specific convection reflow profile. Surface mount simulation test can be used on all surface mount components (including BGAs and CGAs, where the dip and look method is not appropriate).

Solderability test is considered destructive.

Applicable Specifications & Standards

- IPC/JEDEC J-STD-002: Solderability Tests for Components Leads, Terminations, Lugs, Terminals, and Wires

- MIL-STD-883 Method 2003: Solderability

- MIL-STD-750 Method 2026: Solderability

- MIL-STD-202 Method 208: Solderability

Hermeticity Test

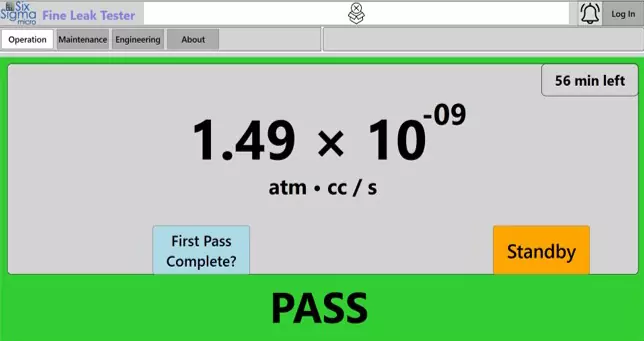

Hermeticity test (also known as fine and gross leak) is used to determine the effectiveness of the seal in microelectronic component packages. If the package seal is damaged or defective, moisture and other contaminants can enter into the package freely and degrade the device’s long-term reliability.

To determine the size of the leak, the volume of air that passes through the leak each second under a pressure difference of 1 atmosphere is obtained. Leak rates greater than 1x10-5 atm-cc/sec are considered gross leak rates; those smaller than 1x10-5 atm-cc/sec are considered fine leak rates [1]. Liquids are typically used to detect gross leaks, while tracer gases are used for fine leak detection.

Six Sigma performs fine leak test using industry-standard mass spectrometer helium leak detectors. Gross leak test is performed using perfluorocarbon fluid bubble detection systems. The methods used for gross leak test cannot be used for fine leak test and vice versa.

Devices cannot be constructed of organic materials to pass as hermetically-tested. With the exception of ink marking, nearly all organic materials will absorb enough helium to fail this test. Even bumper tape or part number labels can cause a false failure, so they must be removed prior to testing.

Hermeticity test is considered non-destructive.

[1] H. Greenhouse, Hermeticity of Electronic Packages (William Andrew Publishing, LLC, New York, USA), p. 269 (2000).

Applicable Specifications & Standards

- JEDEC JESD22-A109: JEDEC Standard, Hermeticity

- MIL-STD-883 Method 1014: Seal

- MIL-STD-202 Method 112: Seal

Ionic Cleanliness Test

Ionic cleanliness test is used to measure the conductivity (or resistivity) of a sample which can be related to the amounts of ionic materials present. The resistivity of the solution decreases as the level of ionic contamination increases. There are two types of contaminants: ionic and non-ionic.

Ionic contaminants are typically flux residues or harmful materials that are picked up or left behind during the process. They are generally water-soluble organic or inorganic acids or salts. They contain molecules or atoms that are conductive when in solution which can disassociate into either positively or negatively-charged species and increase the overall conductivity of the solution. These ionic contaminants can degrade the reliability of the electronic components and assemblies as they contribute to current leakage between the circuitry, promote dendrite growth, and increase the risk of corrosion.

Shown in Figure 1 is a typical contamination vs. time plot. As per IPC-TM-650 Method 2.3.25 (ROSE Method), ionic residues are expressed as equivalents of sodium chloride (NaCl) in micrograms per unit surface area. The sample passes the test if the conductivity (or resistivity) is less than or equal to the target conductivity (or resistivity) value, and fails otherwise.

Ionic cleanliness test is considered non-destructive.

Applicable Specifications & Standards

- IPC/EIA J-STD-001: Requirements for Soldered Electrical and Electronic Assemblies

- IPC-TM-650 Method 2.3.25: Detection and Measurement of Ionizable Surface Contaminants by Resistivity of Solvent Extract (ROSE)

Physical Dimensions Test

Six Sigma Microelectronics utilizes optical Coordinate Measuring Machines (CMMs), toolmaker’s microscopes, optical comparators, and other high-resolution instruments (calibrated and traceable to NIST standards) to verify that the component’s external physical dimensions are in conformance with customer, government, and/or industry requirements.

Physical dimensions test is considered non-destructive.

Applicable Specifications & Standards

- MIL-STD-1835: Electronic Component Case Outlines

- MIL-STD-883 TM2016: Physical Dimensions

Column Pull Test

Column pull test was originally developed by Six Sigma in 2005 and included in MIL-STD-883 TM2038 in 2013. Column pull test is used to determine the failure mode and strength of solder columns after column attach. This test can distinguish failures between the fillet and substrate or in the pad itself. Since Six Sigma solder columns are designed to be ductile, the failure mode is typically along the length of the column (which is the preferred mode).

Column pull is a destructive test.

Applicable Specifications & Standards

- MIL-STD-883 Method 2038: Solder Column Package Destruction Lead Pull Test

Ball Shear Test

Ball shear test is performed to determine the ability of Ball Grid Array (BGA) solder balls to withstand mechanical shear forces that may be applied during BGA manufacturing and handling operations. In addition, Ball Shear Test is a valuable process monitor to determine the reliability of the ball attach process. It can be performed at any time prior to second level attachment to the printed circuit board (PCB) or stress testing of the BGA module.

During ball shear test, balls are sheared individually. The loading rate, the maximum load, and failure mode of each sheared solder ball are then collected.

Ball shear test is a destructive test.

Applicable Specifications & Standards

- JESD22-B117: JEDEC Standard, Solder Ball Shear

Other Test Services

Six Sigma also performs Lead Fatigue, Mark Permanency, and Tape Peel Test.

Lead Fatigue

Lead fatigue is performed to check the resistance of the leads to metal fatigue. The equipment requires attaching devices, clamps, supports, or other suitable hardware necessary to apply a repeated bending stress on the lead throughout the specified bend angle. The applied load, bend angle, and number of cycles required depend upon the package type. Any device that exhibits evidence of breakage, loosening, or relative motion between the terminal lead and the device body when stress is removed is considered a device failure.

Lead fatigue is a destructive test.

Applicable Specifications & Standards

- MIL-STD-883 Method 2004: Lead Integrity

Mark Permanency Test

Mark permanency test is used to verify that the component markings remain legible when subjected to repeated cleaning with common solvents. It also verifies that the solvents will not cause deterioration of the materials or finishes. The process is performed by subjecting the components to repeated soaking and brushing of various commonly-used solvents in printed circuit board (PCB) assembly. In addition, gold-lidded devices are subjected to “pre-conditioning” in heated RMA flux. After the test, the components are inspected for marking failure or degradation of the package. This test is applicable for all package types but does not apply to laser-marked components.

Mark permanency is a non-destructive test.

Applicable Specifications & Standards

- JESD22-B107: JEDEC Standard, Marking Permanency

- MIL-STD-883 Method 2015: Resistance to Solvents

- MIL-STD-750 Method 1022: Resistance to Solvents

Tape Peel Test

Prior to tape & reel, a peel test is performed by peeling the carrier tape to measure the peel force. This information is then used to evaluate the bond strength between the carrier tape and the cover tape. If no issues are found, then the tape & reel process is performed.