Component Services

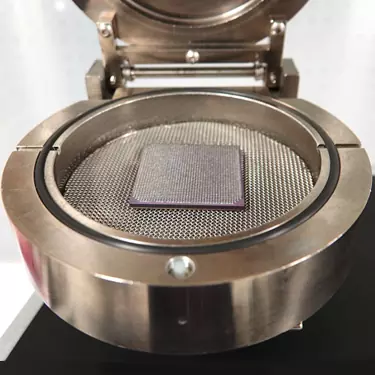

Six Sigma Microelectronics performs specialized microelectronic component modification services, such as Column Attach, Ball Attach & Reballing, and Hot Solder Dip.

Six Sigma’s column attach and hot solder dip manufacturing lines are

MIL-PRF-38535 QML-Q, V, & Y certified by the US Department of Defense.

Test Services

Test Services include: Solderability, Hermeticity, Ionic Cleanliness, Physical Dimensions, Column Pull, X-Ray Fluorescence (XRF), Ball Shear, and Lead Fatigue.

Six Sigma has been awarded Commercial Laboratory Suitability for MIL-STD-883 by the US Department of Defense.

Analytical Services

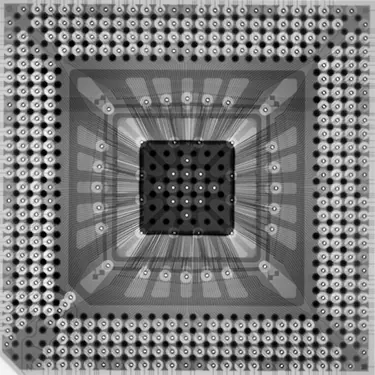

Analytical Services include: 3D X-ray, Acoustic Microscopy, and Metallographic Cross-sectioning.

Six Sigma performs analytical services in accordance with applicable government and industry standards.

News

DoD Announces $10 Million Defense Production Act Title III Agreement With Six Sigma

As part of the nation’s effort to sustain the microelectronics manufacturing capability necessary for national and economic security, and in support of Executive Order 14017, America’s Supply Chains, the Department of Defense recently entered a $10 million agreement with Six Sigma utilizing Defense Production Act (DPA) Title III authorities.

Read More →SIX SIGMA Solder Column Technology used in CFEsat

SIX SIGMA is pleased to announce that it’s SolderQuik® column grid array technology has been used to ruggedize FPGA microcircuits on-board the Cibola Flight Experiment Satellite (CFEsat)

Read More →Hot Solder Dip and Minimizing Thermal Gradients

The semiconductor industry’s move to pure-tin finishes is creating a dilemma for the high-reliability community. Most military and aerospace companies forbid the use of pure-tin because of the risk of tin whiskers. To resolve this dilemma, hot solder dip is being implemented to convert components to alternative finishes. Read the PDF.

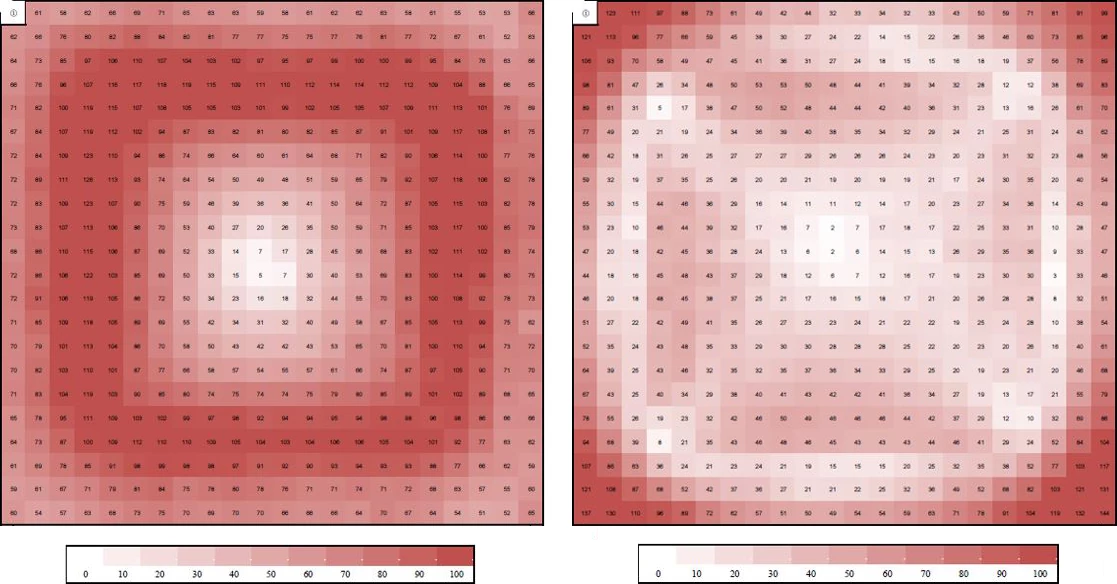

Read More →Actel CCGA Board Level Testing Report

Traditional Ceramic Quad Flat Pack (CQFP) or Ceramic Pin Grid Array (CPGA) packages are no longer suitable for today’s high I/O count FPGA devices. Higher pin-count packages such as Ceramic Column Grid Array (CCGA) become necessary for packaging today’s high-density FPGA devices. CCGA represents a key leveraging technology that offers high density packaging for high…

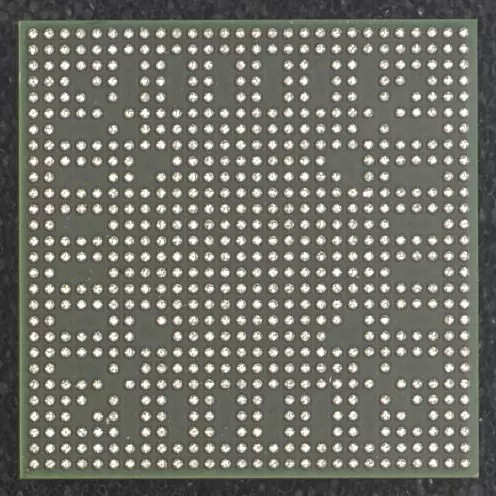

Read More →BGA Reballing for Military & Aerospace Applications Poster

Poster with photos and process flow of the BGA reballing process for military and aerospace applications.

Read More →Converting Ball Grid Array to Column Grid Array Poster

Poster with photos and diagrams showing ball grid array components being converted to column grid array.

Read More →